Transform Collision Repair with

AI-Assisted Precision

Empower your shop with intelligent repair planning

AI-Powered Accuracy

Identify missing OEM procedures automatically

Reduce Supplements

Minimize documentation issues from the start

Faster Cycle Times

Streamline repair planning and approvals

Today's Repair Reality

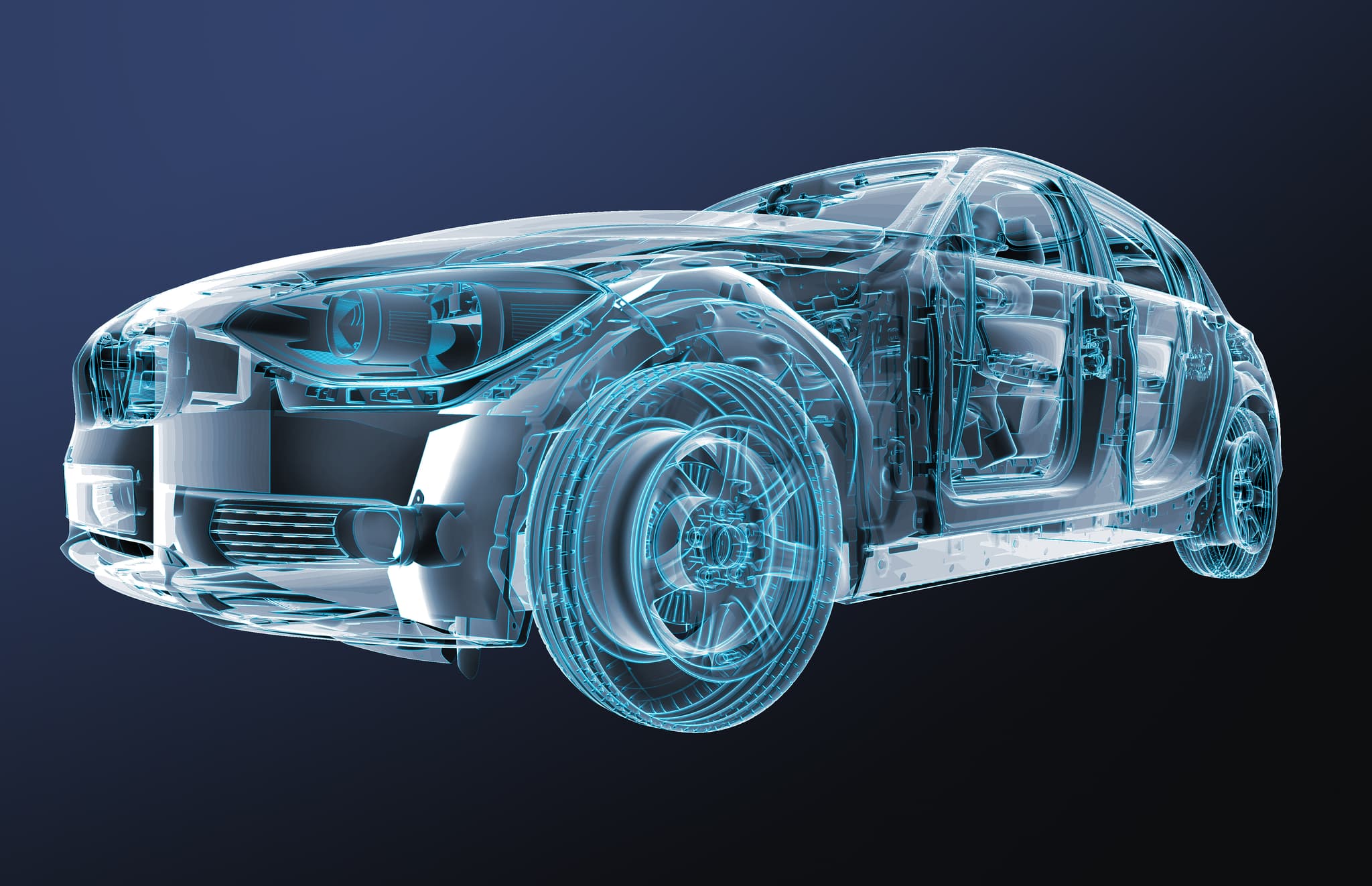

Modern vehicles demand modern solutions

Technology Outpacing Methods

ADAS, EVs, and multi-material construction have transformed every repair. Traditional approaches miss critical requirements.

Hidden Profit Leaks

Missed procedures and supplements delay payment and reduce margins. Money left on the table daily.

Manual Research Bottleneck

Hours spent searching through documentation. Your team's expertise trapped in administrative tasks.

Rising Compliance Requirements

Every repair needs complete documentation. OEM procedures are requirements, not guidelines.

Intelligent Repair Planning

Where reasoning meets efficiency

Reasoning Engine at Work

Kaizen connects the dots: damage location + equipment + OEM rules = complete requirements. Not just search - intelligent analysis.

Complete Plans, Better Margins

Identify all billable operations upfront. Reduce supplements, accelerate approvals, improve cash flow.

Minutes Instead of Hours

Transform research from manual burden to automated intelligence. Free your team for value-added work.

Every Decision Documented

Automatic documentation linking requirements to OEM sources. Complete audit trail for confidence.

The Numbers Don't Lie

Industry data validates the challenges you face daily. Here's what the latest research reveals about the collision repair landscape.

of repairs require supplements

CCC, Q3 2024

of new cars have ADAS systems

NHTSA, 2023

technicians needed over 5 years

TechForce, 2023

of ADAS calibrations missed initially

CCC, Q3 2024

higher cost for EV repairs

Mitchell, Q3 2024

revenue decline reported by shops

Focus Advisors, 2024

These aren't just numbers—they're the reality of your business. Kaizen transforms these challenges into opportunities.

How It Works

The Power of Intelligent Reasoning

Input: Damage + Vehicle Data

Provide VIN, photos, and damage location. Kaizen maps all equipment and understands the context.

Reasoning: Connect the Dots

Kaizen doesn't just search - it thinks:

- Damage here + sensor there = specific restrictions

- This repair method + that equipment = new requirements

- One procedure triggers another, which triggers another

Output: Complete, Justified Plan

Every step explained, every requirement traced to its source. The reasoning is transparent and verifiable.

Input: Damage + Vehicle Data

Provide VIN, photos, and damage location. Kaizen maps all equipment and understands the context.

Reasoning: Connect the Dots

Kaizen doesn't just search - it thinks:

- Damage here + sensor there = specific restrictions

- This repair method + that equipment = new requirements

- One procedure triggers another, which triggers another

Output: Complete, Justified Plan

Every step explained, every requirement traced to its source. The reasoning is transparent and verifiable.

Key Shop Benefits

Better research leads to better repair plans and better outcomes for your shop

Stop Revenue Leakage

Capture missed billable operations and reduce costly supplements that eat into your margins

Cut Front Office Time

Complete repair plans in minutes, not hours. Free up staff for revenue-generating work

Reduce Supplement Rates

Get it right the first time. Fewer supplements mean faster cycle times and happier customers

Document Every Decision

Complete OEM audit trail protects your shop from liability and supports every line item

Ensure Safe Repairs

Never miss critical procedures. Sleep better knowing every repair meets OEM standards